Categories: Hydrogen Fuel Cell Testing Machine

Follow:

Introduction

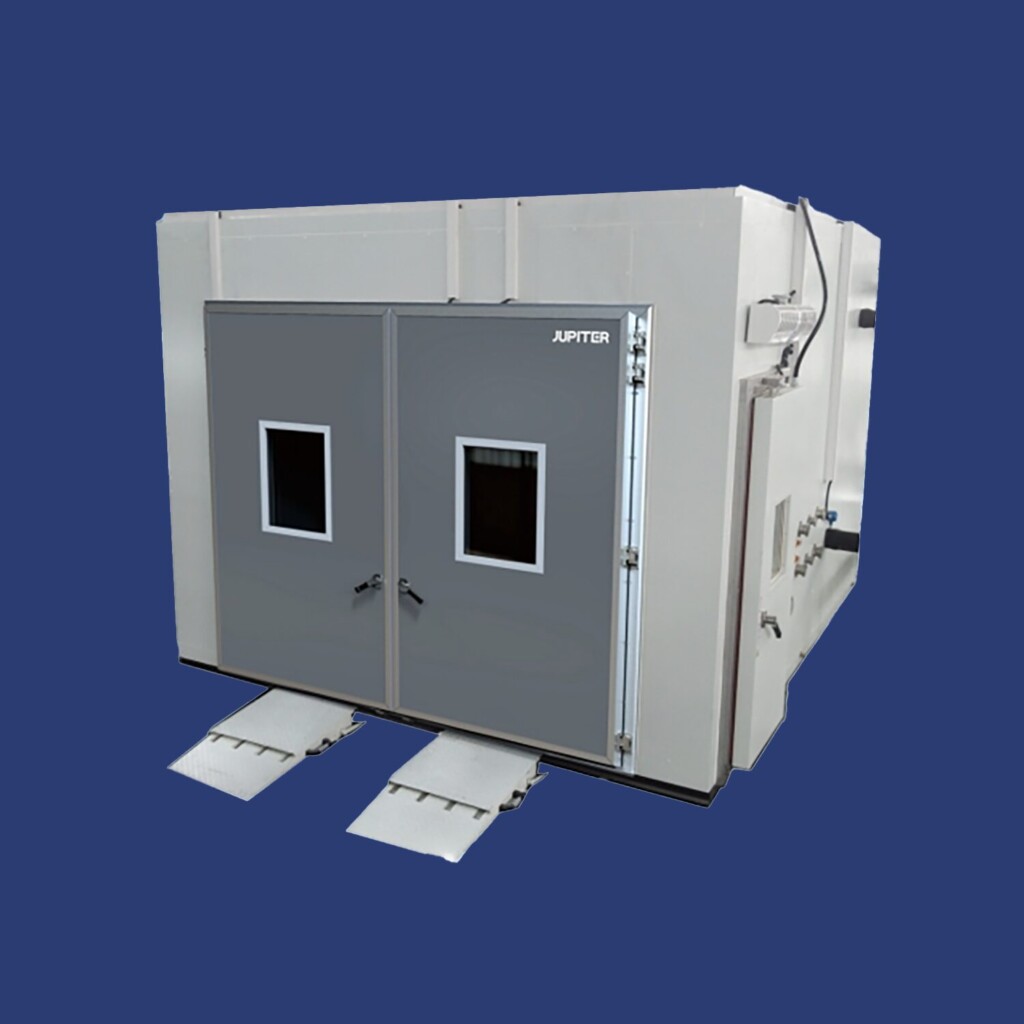

The reliability and performance of hydrogen fuel cell systems play a crucial role in promoting the development of hydrogen energy technology. In order to ensure the stable operation of various series of hydrogen fuel cell systems under different environmental conditions, our company has developed the UC series walk-in hydrogen fuel cell system environmental test chamber.

Advanced equipment designed specifically for hydrogen fuel cell systems can undergo environmental simulation tests in accordance with standards such as GB/24554-2009.

The experimental module includes core components such as the cabin, refrigeration unit, oil heating unit, high-altitude simulation unit, and fresh air unit, ensuring precise environmental control and simulation of the hydrogen fuel cell system during the testing process. It has the ability to simulate the environment under a combination of multiple factors such as temperature, humidity, and low air pressure in the natural environment (requiring an optional high-altitude simulation system). After integrating the software and hardware systems with the test bench, the working status of the test chamber can be remotely monitored and controlled through the main control system of the test bench. Parameters such as temperature, humidity, and height can be individually programmed and controlled, or linked and controlled through the main control program of the test bench to ensure the accuracy and controllability of the test process.

Solutions

Primary Purpose

| JHM Series (Internal Heat Dissipation) Hydrogen Fuel Cell System Environmental Test Chamber | |||||

| Model | JHM60T-I/LP(WP) | JHM70T-I/LP(WP) | JHM100T-I/LP(WP) | JHM120T-I/LP(WP) | JHM150T-I/LP(WP) |

| Adaptation system | 120KW | 150KW | 200KW | 250KW | 300KW |

| Hydrogen air pre cooling device | JHP3-T | JHP4-T | JHP5-T | JHP6-T | |

| Maximum fresh air volume | 800 m³/h | 1200 m³/h | |||

| Internal volume | 60 m³ | 72 m³ | 100 m³ | 120 m³ | 150 m³ |

| External dimensions of the cabin (D*W*H) | 5700mm*4300mm*4300mm | 6500mm*4300mm*4300mm | 6800mm*5300mm*4700mm | 7800mm*5300mm*4700mm | 8050mm*6300mm*4700mm |

| Refrigeration unit size (D*W*H) | 2950mm*1850mm*2400mm*2 | 2950mm*1850mm*2400mm*2 | 2950mm*1850mm*2400mm*2 | 2950mm*1850mm*2400mm*3 | 2950mm*1850mm*2400mm*3 |

| Dimensions of high-altitude units (D*W*H) | 2800mm*1700mm*2500mm | ||||

| Size of fresh air unit (D*W*H) | 3500mm*1100mm*1900mm | 3500mm*1200mm*2000mm | |||

| Hydrogen pre cooling size (D*W*H) | 1800mm*1000mm*2600mm | 2250mm*1250mm*2600mm | |||

| General Technical Indicators | |||||

| 1.1 Temperature range | -40℃~+90℃ | ||||

| 1.2 Heating rate | ≥ 1 ℃/min (-40 ℃~+90 ℃ range Average throughout the entire process, with hydrogen fuel cell system and tooling, the system does not dissipate heat. | ||||

| 1.3 Cooling rate | ≥ 1 ℃/min (-40 ℃~+90 ℃ range Average throughout the entire process, with hydrogen fuel cell system and tooling, the system does not dissipate heat. | ||||

| 1.4 Temperature deviation | ≤ ± 0.2 ℃ | ||||

| 1.5 Temperature fluctuation | ≤ ± 0.5 ℃ (Static without thermal load) ≤ 2.0 ℃ (Dynamic test condition) |

||||

| 1.6 Temperature uniformity | ≤ 2.0 ℃ (Unload, atmospheric, static) | ||||

| Humidity range | 20% RH~95%RH | ||||

| Temperature range during humidity test | 20 ℃~85 °C | ||||

| Humidity deviation | (Humidity>75% RH)+2~-3% RH | ||||

| Pipeline pressure range | Atmospheric pressure~40kPa (approximately 6100m above sea level) | ||||

| Pipeline pressure accuracy | 2kPa (loaded, dynamic for 3 minutes, with a maximum of ≤ ± 5kPa within 3 minutes) | ||||

| Pipeline pressure reduction rate | Atmospheric pressure~40kpa ≤ 10min | ||||

| Pipeline pressure recovery rate | 40kPa~atmospheric pressure ≤ 10min | ||||

| Pipeline pressure deviation | ≤±2kPa | ||||

| JHM Series (External Heat Dissipation) Hydrogen Fuel Cell System Environmental Test Chamber | |||||

| Model | JHM15T-O/LP(WP) | JHM24T-O/LP(WP) | |||

| Adaptation system | 120KW | 150KW | 200KW | 250KW | 300KW |

| Hydrogen air pre cooling device | HY3-TC | JHP4-T | JHP5-T | JHP6-T | |

| Maximum fresh air volume | 800 m³/h | 1200 m³/h | |||

| Internal volume | 15 m³ | 24 m³ | |||

| External dimensions of the cabin (D*W*H) | 3800mm*2800mm*3100mm | 4500mm*3300mm*3200mm | |||

| Refrigeration unit size (D*W*H) | 2200mm*1200mm *2000mm |

2200mm*1400mm*2000m | 2950mm*1850mm *2400mm |

||

| Dimensions of high-altitude units (D*W*H) | 2800mm*1700mm*2500mm | ||||

| Size of fresh air unit (D*W*H) | 3500mm*1100mm*1900mm | 3500mm*1200mm*2000mm | |||

| Hydrogen pre cooling size (D*W*H) | 2200mm*1250mm*2600mm | 2400mm*1250mm*2600mm | |||

| General Technical Indicators | |||||

| Temperature range | -40℃~ +90℃ | ||||

| Heating rate | ≥ 1 ℃/min (-40 ℃~+90 ℃ range Average throughout the entire process, with hydrogen fuel cell system and tooling, the system does not dissipate heat. | ||||

| Cooling rate | ≥ 1 ℃/min (-40 ℃~+90 ℃ range Average throughout the entire process, with hydrogen fuel cell system and tooling, the system does not dissipate heat. | ||||

| Temperature deviation | ≤ ± 0.2 ℃ | ||||

| Temperature fluctuation | ≤ ± 0.5 ℃ (Static without thermal load) ≤ 2.0 ℃ (Dynamic test condition) |

||||

| Temperature uniformity | ≤ 2.0 ℃ (Unload, atmospheric, static) | ||||

| Humidity range | 20% RH~95%RH | ||||

| Temperature range during humidity test |

20℃~85°C | ||||

| Humidity deviation | (Humidity>75% RH)+2~-3% RH

(Humidity<75% RH)± 5% RH |

||||

| Pipeline pressure range | Atmospheric pressure~40kPa (approximately 6100 m above sea level) | ||||

| Pipeline pressure accuracy | 2kPa (loaded, dynamic for 3 minutes, with a maximum of ≤ ± 5kPa within 3 minutes) | ||||

| Pipeline pressure reduction rate | Atmospheric pressure~40 kpa ≤ 10 min | ||||

| Pipeline pressure recovery rate | 40kPa~atmospheric pressure ≤ 10 min | ||||

| Pipeline pressure deviation | ≤ ±2kPa | ||||

Copyright © 2024 SICHUAN JUPITER TECHNOLOGY CO.,LTD. All Rights Reserved Privacy Policy

message