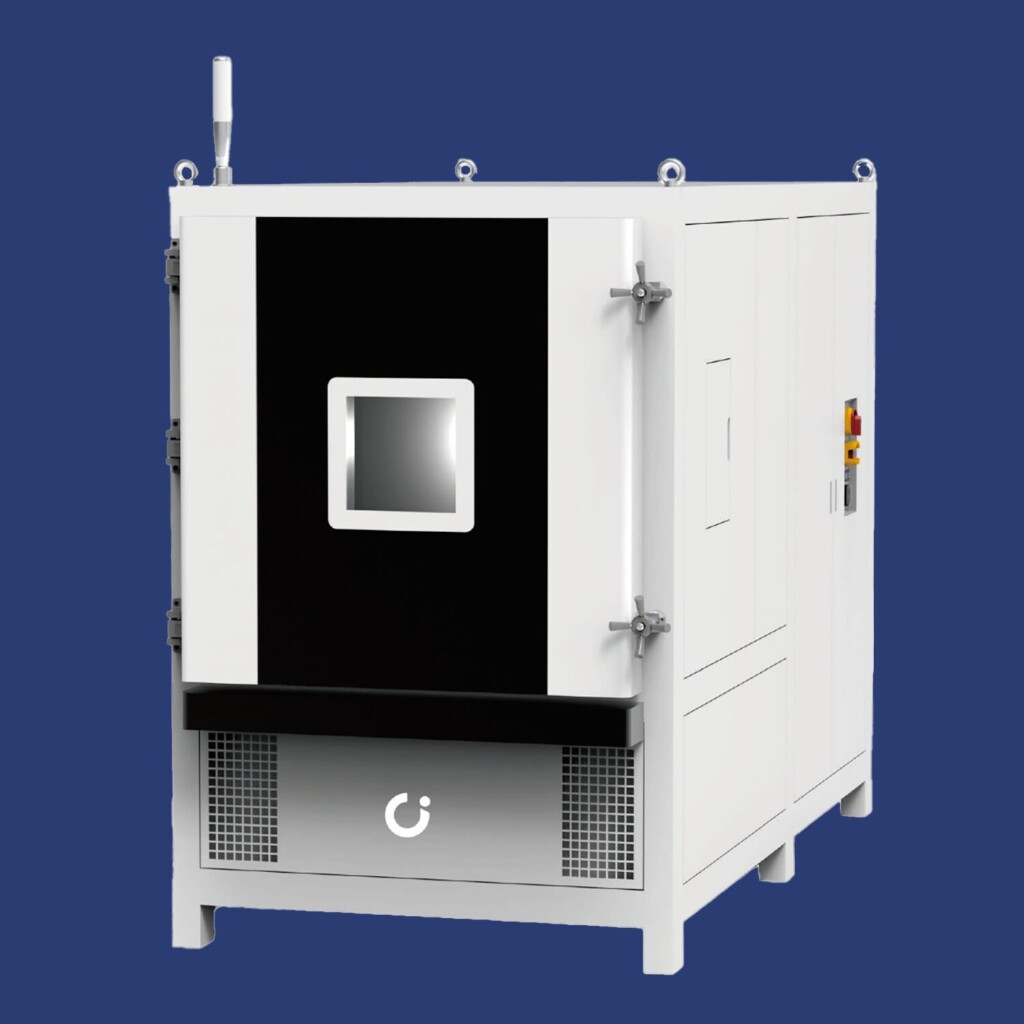

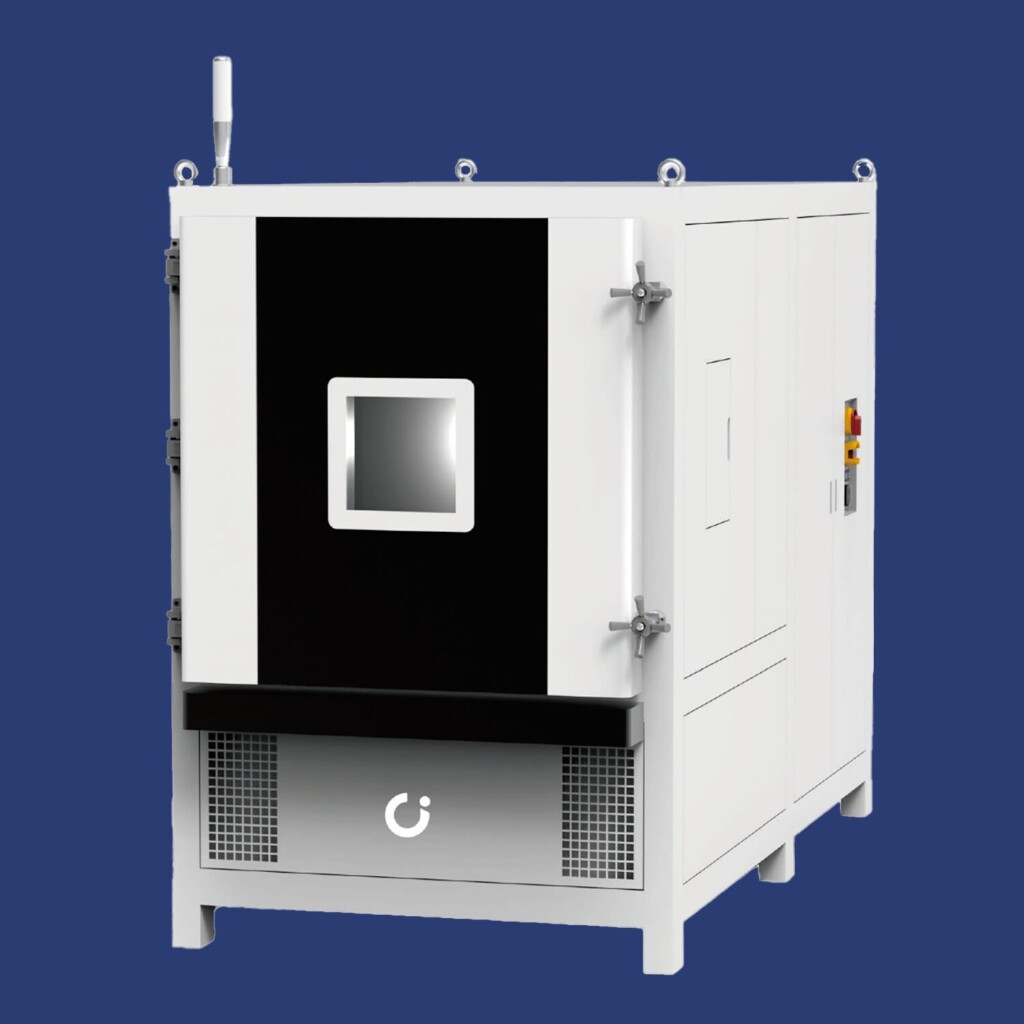

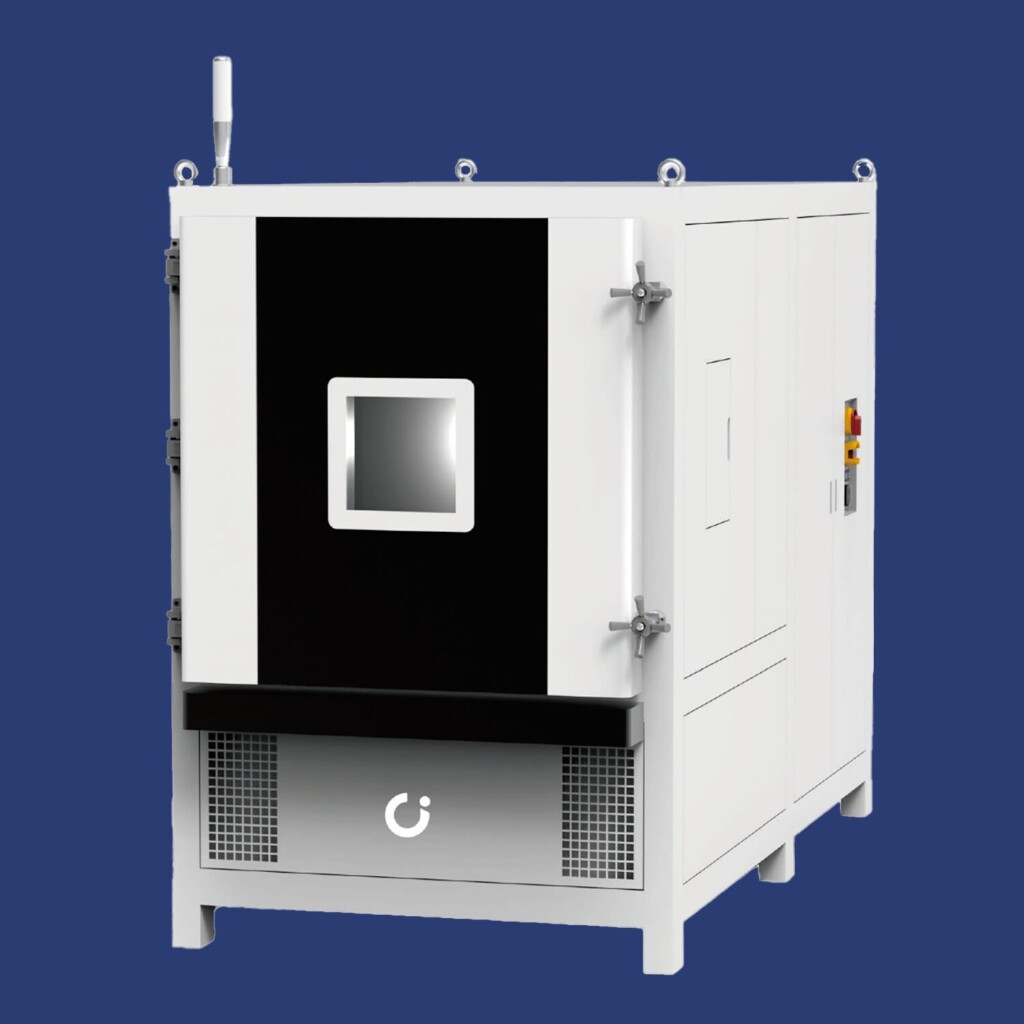

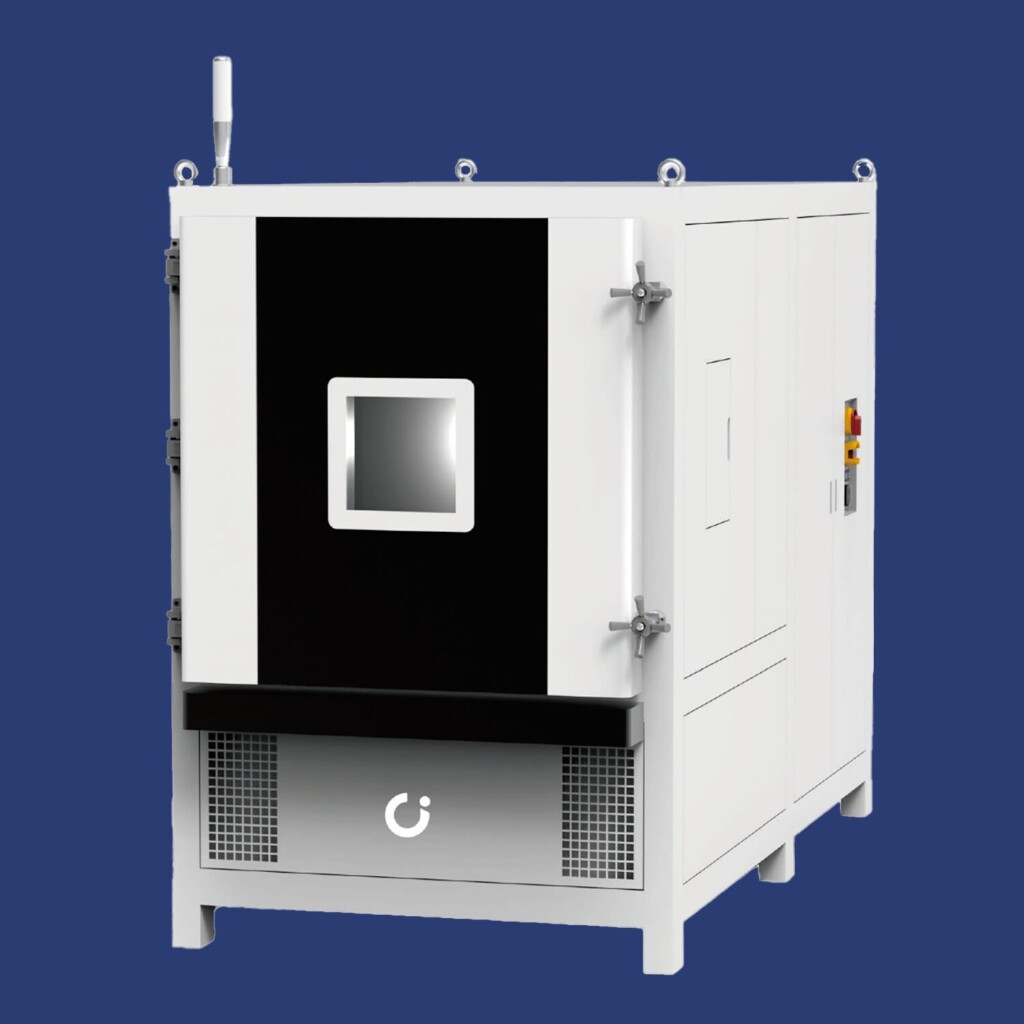

Categories: Low Pressure Enviromental Test Chamber

Follow:

Introduction

High – low temperature and low pressure test chamber is a simulation of high altitude, high altitude, (plateau area) climate for storage and transport reliability test, and can be simultaneously electrified on the test piece for electrical performance parameters of the test equipment. Applicable to the defence industry, aerospace industry automation components, automotive parts, batteries, flat panel display group industry and related products for high temperature, low temperature, height (not higher than 30,000 m above sea level or 45,000 m) and high and low temperature cycling test, temperature and altitude of the integrated test, high and low temperature test this chamber can be used for heat dissipation test specimens and non-heat dissipation test specimen test.

Safety & Protections

Power supply under-voltage, over voltage, missing phase, phase sequence error protection; 3 kinds of overtemperature protection Heater short circuit protection; Compressor overpressure/ overload/ protection: Humidifier fault protection: Blower Motor overload/overheat protection; Panel over current protection, earth leakage protection: Vacuum pump overload protection: compressed air inadequate pressure protection.

Application

Mainly used in aviation, aerospace, information, electronics and other fields to determine the instrumentation, electronic products, materials, components, equipment, etc. under the single or simultaneous condition of low pressure, high temperature, low temperature for environmental adaptability and reliability test or measured technical data of samples.

Options

| High-Low Temperature(Humidity) and Low Pressure Vacuum Chamber | |||||

| Model | JCP250(C) | JCP500(C) | JCP1000(C) | JCP2000(C) | |

| Nominal inside volume(L) | 250L | 500L | 1000L | 2000L | |

| Performance | Temperature range | -40℃~+150℃ for model without suffix C, -70℃~+150℃ for model with suffix C | |||

| Humidity range | 20%~98%R.H | ||||

| Temperature fluctuation | ≤±0.5 (Under atmospheric pressure) | ||||

| Temperature uniformity | ≤2℃ | ||||

| Temperature deviation | ≤±2℃ (Under atmospheric pressure) | ||||

| Humidity deviation | -3~+2%R.H.(75%R.H.above), ±5%R.H.(75%R.H.following) | ||||

| Heating rate (average) | 2℃/min | 2℃/min | 2℃/min | 2℃/min | |

| Cooling rate (average) | 1℃/min | 1℃/min | 1℃/min | 1℃/min | |

| Remarks | Above indicators are measured in no load at ambient temperature of 20±2°C(According to GB/T 5170.2-2017) | ||||

| Air pressure range | Ventricular pressure~0.5kPa | ||||

| Air pressure error | ±2kPa(≥40kPa), ±5%(2kPa~40kPa), ±0.1kPa(≤2kPa) | ||||

| Pressure reduction time | Under atmospheric pressure~1kPa, nearly 30min | ||||

| Pressure recovery time | ≤10kPa/min | ||||

| Internal dimension(mm) | D*W*H | 550*600*750 | 700*800*900 | 1000*1000*1000 | 1400*1200*1200 |

| External dimension(mm) | D*W*H | 2200*1060*1900 | 2500*1260*2050 | 2720*1460*2130 | 3150*1650*2050 |

| Test hole | 1 Φ100 | 2Φ100 | |||

| Stainless steel shelf (2 pcs in standard configuration) | Bearing 20kg/pc | Bearing 50kg/pc | |||

| Using environment temperature | 0~+40℃ | ||||

| Shell | Sprayed steel plate | ||||

| Interior | SUS304 stainless steel | ||||

| Cooling mode | water-cooling, (water temperature7~28℃, hydraulic pressure0.2~0.4Mpa, to ensure cooling performance) | ||||

| Controller | 7′ Color touch screen Controller | ||||

| Communication function | RS485 or standard RJ45 network interface, standard USB interface | ||||

| Gas source | Crushing air 0.4~0.7MPa | ||||

| Power supply | 380V+10%/50HZ+1,three-phase-five-wire system (3P+N+G) | ||||

| Installed capacity(kw)(-/-C) | 20/23 | 25/30 | 37/42 | 45/54 | |

| Weight(kg) | 1200 | 2100 | 3200 | 4800 | |

| Meet the testing method | GB2423.1-2008,GB2423.2-2008,GB2423.21-2008,GJB150.3-2009, GJB150.4-2009, GJB150.2-2009 (excluding rapid bulging), GJB150.6-2009, GB/T 2423.27-2008 Test Z/AMD Low Temperature/Low Pressure/Wet Heat Continuous Integration, GJB150,19-2009 Temperature-Humidity-Height, GJB 150.24A-2009 Temperature-Temperature-Vibration-Height (excluding dynamic) | ||||

| Safety precautions | Power supply undervoltage, overvoltage, phase loss, and phase sequence error protection; Triple over temperature protection; Short circuit protection for heater Refrigerator overpressure/overload protection; Overload/overheating protection for blower motor; Control board overcurrent protection and leakage Protection, vacuum pump overload protection, compressed air undervoltage protection. | ||||

| Optional | Special test holes, aviation plugs, terminals, special shelves, etc., optional with 15s quick decompression and 0.1s explosive decompression | ||||

Copyright © 2024 SICHUAN JUPITER TECHNOLOGY CO.,LTD. All Rights Reserved Privacy Policy

message