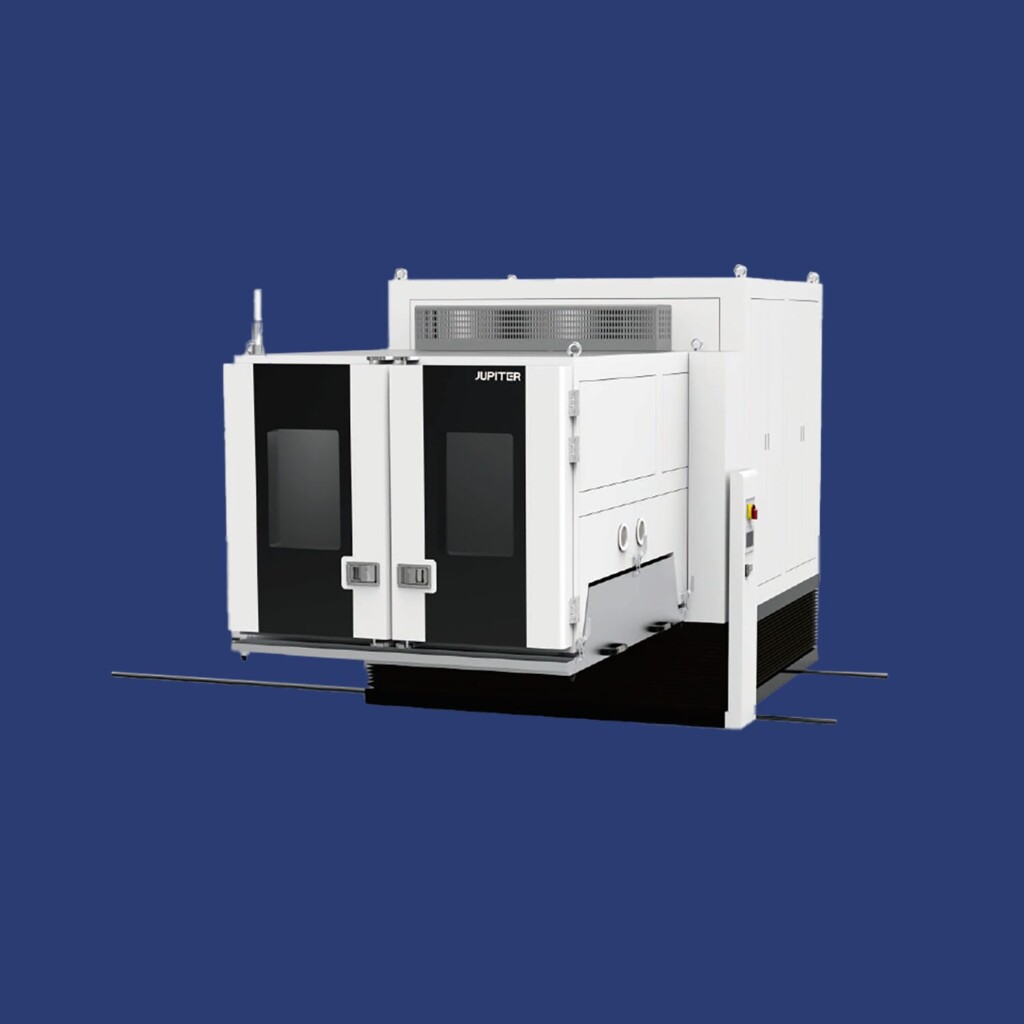

-1-1024x1024.jpg)

Categories: Temperature/Humidity/Vibration Chamber

Follow:

Introduction

Three integrated test chamber is simulated high temperature, low temperature, high and low temperature cycle, as well as constant damp heat and alternating damp heat test, at the same time in the vibration table with the connection, can achieve the temperature, humidity, vibration of the three factors of the integrated test instrumentation. Generally applicable to aerospace, aviation, petroleum, chemical, electronics, communications and other scientific research and production units to test products, materials in the transport and actual use of the process of temperature, humidity and vibration of the composite environmental changes in the adaptability of the exposure of the product defects, is the development of new products, prototype testing, product qualification tests throughout the process of the indispensable and important means of testing.

Safety & Protections

Power supply under voltage, over-voltage, missing phase, phase sequence error protection; 3 kinds of over temperature protection Heater short circuit protection; Compressor over pressure / overload / lack of oil protection; Humidifier fault protection; Blower Motor overload / overheat protection; Panel over-current protection, earth leakage protection; cooling water shortage protection.

Application

The temperature, humidity and vibration three integrated test chamber is mainly used to test the specimen temperature stress, can be widely used in aerospace, aviation, shipping, electronics, metallurgy, petroleum, chemical industry and other fields, for high and low temperature test, constant temperature and humidity test, high and low temperature alternating humidity test, temperature, humidity and vibration three integrated test. In order to determine the adaptability and reliability of the test specimen in the surrounding atmosphere when the temperature changes rapidly.

Options

1. Special cable port, special shelf;

2. Dry air purge system;

3. Liquid nitrogen function.

Product Features

1.Advanced air duct design, the application of CFD flow simulation technology, adjustment and optimization of the air flow field inside the environmental chamber to ensure that the environmental test chamber temperature uniformity and volatility, and effective control of the evaporator frost phenomenon.

2.Excellent energy-saving and consumption reduction technology, the control system adopts PWM cold control mode heating without refrigeration, refrigeration without heating, energy saving of more than 40% under constant operating conditions.

3.Diversified structural forms, three integrated products can be based on the user’s site conditions and the size of the chamber volume, to provide self-lifting, scissors and hydraulic platform, gantry (mainly for large three integrated) three structural modes.

| Temperature/Humidity/Vibration Chamber | |||||

| Model | JC500CVH | JC1000CVH | JC1700CVH | JC3400CVH | |

| Nominal inside volume(L) | 500L | 1000L | 1700L | 3400L | |

| Performance | Temperature range | -70℃~+150℃ | |||

| Humidity range | 20%~98%R.H. | ||||

| Temperature fluctuation | ≤±0.5 | ||||

| Temperature uniformity | ≤2℃ | ||||

| Temperature deviation | ≤±2℃ | ||||

| Humidity deviation | -3~+2%R.H.(75%R.H.above), ±5%R.H.(75%R.H.below) | ||||

| Heating rate (Average/ linear, -55~+85℃) | 3℃/min | ||||

| Cooling rate (Average/ linear, -55~+85℃) | 1℃/min | ||||

| Remarks | Above indicators are measured in no load at ambient temperature of 20±2°C(According to GB/T 5170.2-2017) | ||||

| Internal dimension(mm) | D | 800 | 1000 | 1200 | 1500 |

| W | 800 | 1000 | 1200 | 1500 | |

| H | 800 | 1000 | 1200 | 1500 | |

| Vibrostand size (mm) | Horizontal stand≤500*500 Vertical stand ≤Φ500 |

Horizontal stand≤700*700 Vertical stand ≤Φ700 |

Horizontal stand≤900*900 Vertical stand ≤Φ900 |

Horizontal stand≤1200*1200 Vertical stand ≤Φ1200 |

|

| Inspection window | One 450*450 | Two 350*450 | |||

| Test hole | 2Φ100 | ||||

| Stainless steel shelf (2 pcs in standard configuration) | Bearing 25kg/pc | Bearing 50kg/pc | |||

| Movable floor (2 or 3 pcs) | 1 blind interface board, vertical interface board, 1 horizontal interface board | ||||

| Using environment temperature | 0~35 ℃ | ||||

| Materials | Shell | Sprayed steel plate | |||

| Interior | SUS304 stainless steel | ||||

| Cooling mode | water-cooling, (water temperature 7~28℃, hydraulic pressure 0.2~0.5Mpa, to ensure cooling performance) | ||||

| Controller | Controller | 7′ Color touch screen Controller | |||

| Input | PT100+capacitive humidity sensor | ||||

| Communication function | RS485 or standard RJ45 network interface, standard USB interface | ||||

| Power supply | 380V+10%/ 50HZ+1, three-phase-five-wire system (3P+N+G) | ||||

| Meet the testing method | GB2423.1-2008、GB2423.2-2008、GB2423.3-2008; GB2423.4-2008、GJB150.3-2009、GJB150.4-2009、GJB150.9-2009 | ||||

| Safety precautions | Power supply undervoltage, overvoltage, phase loss, and phase sequence error protection; Triple over temperature protection; Short circuit protection for heaters, Refrigerator overpressure/ overload/ oil shortage protection; humidifier fault protection; Overload/ overheating protection for blower motor; Control board overcurrent protection, leakage protection; Cooling water shortage protection, etc. | ||||

| Optional | 1. Optional special test holes and special shelves; 2. Optional dry air blowing system; 3. Optional liquid nitrogen function. | ||||

Copyright © 2024 SICHUAN JUPITER TECHNOLOGY CO.,LTD. All Rights Reserved Privacy Policy

message