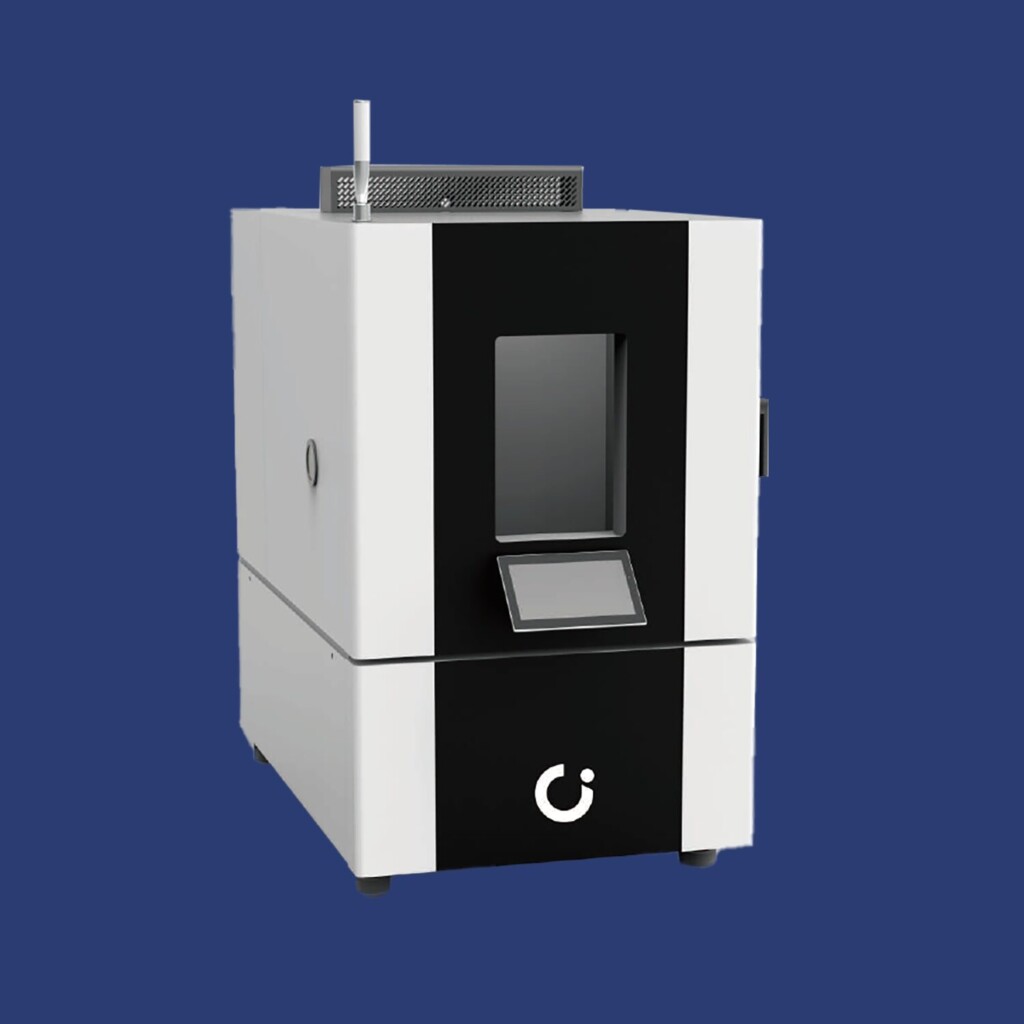

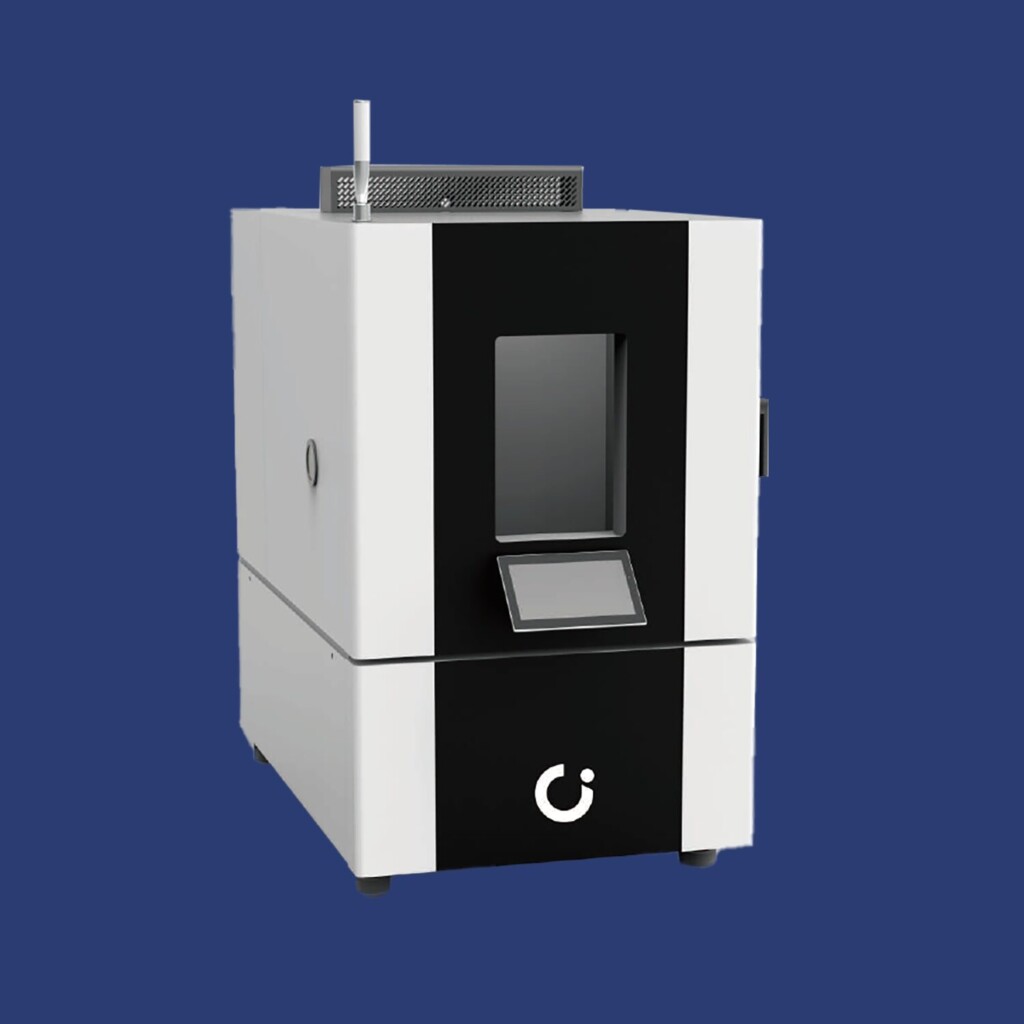

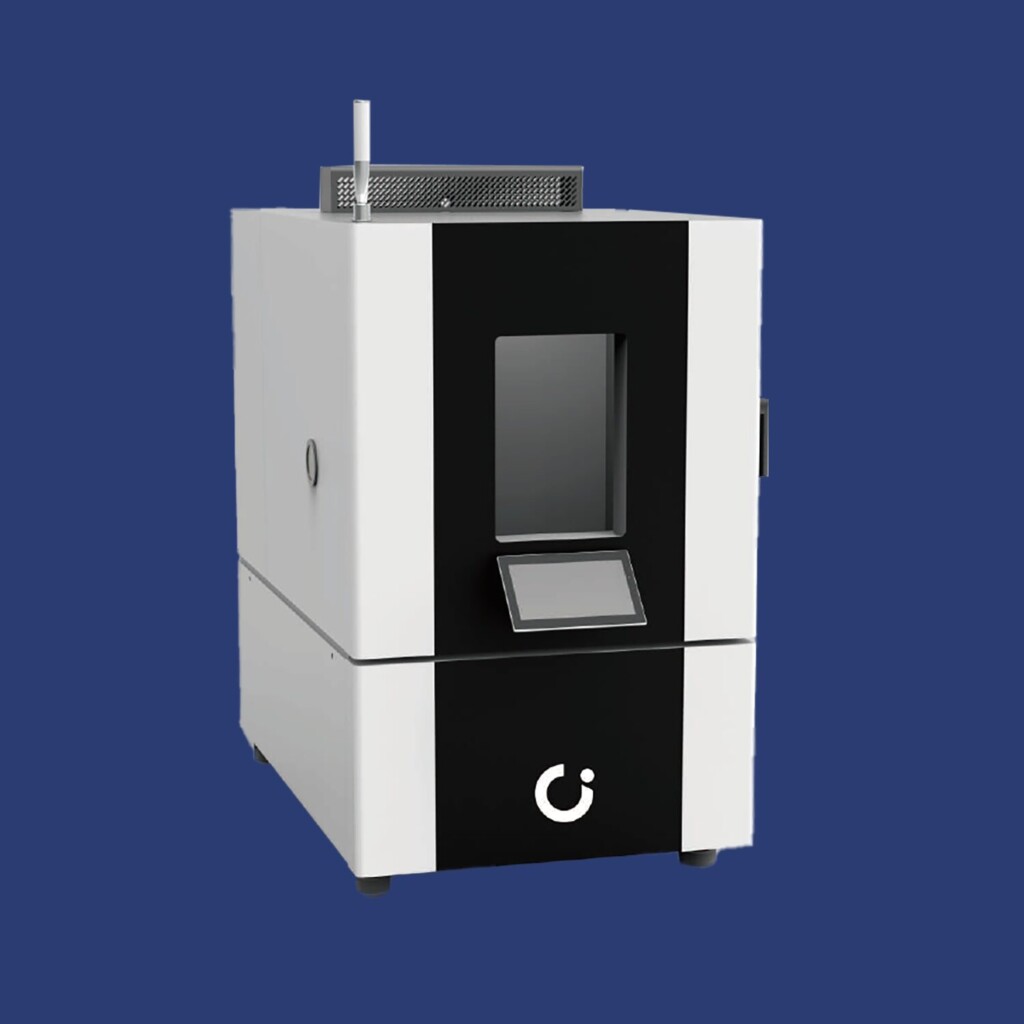

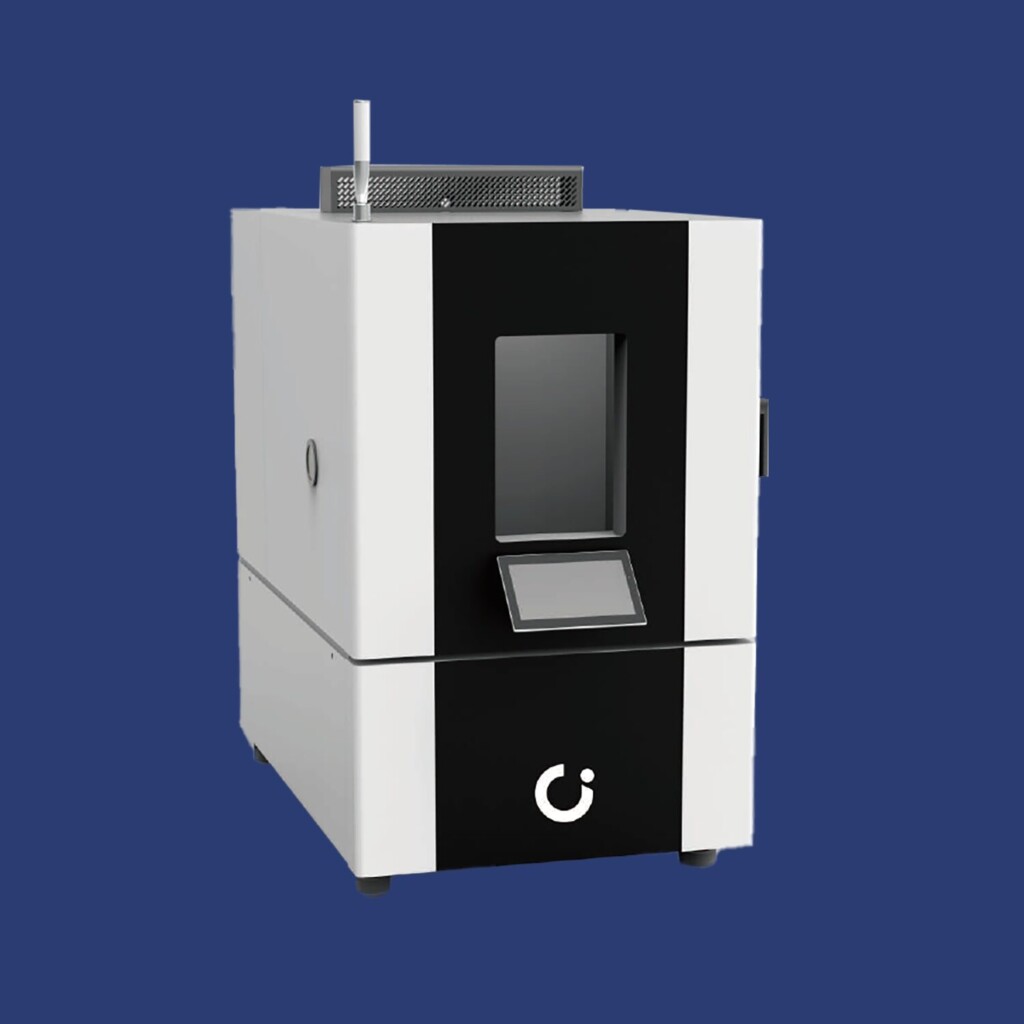

Categories: Rapid Change Temperature Humidity Test Chamber

Follow:

Introduction

Rapid temperature change test chamber is suitable for electronic components, automotive parts and other materials, such as safety performance testing to provide reliability tests, product screening tests, etc., while the test through this equipment can improve the reliability of the product and the quality control of the product. When the material constituting the various components of the product thermal match is poor, or components of the internal stress is greater, the temperature cycle test can trigger the product by the mechanical structure of the defects of the deterioration of the failure of the product.

Safety & Protections

Power supply undervoltage, over-voltage, missing phase, phase sequence error protection; 3 kinds of overtemperature protection; Heater short circuit protection; Compressor overpressure/ overload/ lack of oil protection; Humidifier fault protection; Blower motor overload/overheat protection; Panel over-current protection, earth leakage protection; cooling water shortage protection.

Application

It is used for electronics, electrical products and machine parts to do cold-resistant test, rapid changes in temperature or gradient test and especially used for electronics, electrical products to do environmental stress screening test.

Options

| High-Low Temperature(Humidity) Fast Change Rate Chamber | |||||

| Model | JT/JC250(CL)-5ES | JT/JC500(CL)-5ES | JT/JC1000(CL)-5ES | JT/JC2000(CL)-5ES | |

| JT/JC250(CL)-10ES | JT/JC500(CL)-10ES | JT/JC1000(CL)-10ES | JT/JC2000(CL)-10ES | ||

| JT/JC250(CL)-15ES | JT/JC500(CL)-15ES | JT/JC1000(CL)-15ES | JT/JC2000(CL)-15ES | ||

| JT/JC250(CL)-20ES | JT/JC500(CL)-20ES | JT/JC1000(CL)-20ES | JT/JC2000(CL)-20ES | ||

| JT/JC250(CL)-25ES | JT/JC500(CL)-25ES | JT/JC1000(CL)-25ES | JT/JC2000(CL)-25ES | ||

| Nominal inside volume(L) | 250 L | 500 L | 1000 L | 2000 L | |

| Performance | Temperature range | -70℃~+150℃ | |||

| Humidity range | 20%~98%R.H. (Humidity working range+20℃~+85℃, please refer to the temperature and humidity range diagram for details) | ||||

| Temperature fluctuation | ≤±0.5℃ | ||||

| Temperature uniformity | ≤2℃ | ||||

| Temperature deviation | ≤±2℃ | ||||

| Humidity deviation | -3~+2%R.H.(75%R.H.above), ±5%R.H.(75%R.H.below) | ||||

| Heating rate (Average/ linear, -55~+85℃) | 5℃/min;10℃/min;15℃/min;20℃/min;25℃/min | ||||

| Cooling rate (Average/ linear, -55~+85℃) | |||||

| Remarks | Above indicators are measured in no load at ambient temperature of 20±2°C(According to GB/T 5170.2-2017) | ||||

| Internal dimension(mm)D*W*H | 5ES | 500*700*750 | 700*850*850 | 1000*1000*1000 | 1400*1200*1200 |

| 10/15ES | 500*700(/750)*750 | 700*850*850 | 900*1150*1000 | 1100*1400*1300 | |

| 20ES | 450*750*750 | 600″850*850 | 800*1150*1000 | 1000*1400*1300 | |

| 25ES | 450*750*750 | 600*850*850 | 800*1150*1000 | 1000*1400*1300 | |

| External dimension(mm)D*W*H | 5ES | 1800*950*1800 | 1850*1100*1900 | 2100*1250*2100 | 2500*1450*2400 |

| 10ES | 1800*950*1800 | 2200*1100*2100 | 2300*1400*2500 | 3000*1550*2100 | |

| 15ES | 2200*1000*2100 | 2500*1450*2350 | 2700*1400*2600 | 3500*1950*2100 | |

| 20ES | 2200*1000*2100 | 25001450*2350 | 2700*1400*2600 | 3500*1950*2100 | |

| 25ES | 2300*1000*2100 | 2600*1450*2350 | 2900*1400*2600 | 4000*1950*2100 | |

| Caster | 4 -6 casters | ||||

| Inspection window | 450*450 Equipped with heating device to prevent condensation and frost formation | ||||

| Test hole | 1 Φ100 | 2Φ100 | |||

| Stainless steel shelf (2 pcs in standard configuration) |

Bearing 25kg/pc | Bearing 50kg/pc | |||

| Using environment temperature | 0~40℃ | ||||

| Shell | Sprayed steel plate | ||||

| Interior | SUS304 stainless steel | ||||

| Cooling mode | water-cooling, (water temperature 7~28℃,hydraulic pressure 0.2~0.5Mpa,To ensure cooling performance) | ||||

| Controller | 7′ Color touch screen Controller | ||||

| Communication function | RS485 or standard RJ45 network interface, standard USB interface | ||||

| Power supply | 380V+10%/ 50HZ+1,three-phase-five-wire system (3P+N+G) | ||||

| Meet the testing method | GB2423.1-2008、GB2423.2-2008、GB2423.3-2008; GB2423.4-2008、GJB150.3-2009、GJB150.4-2009、GJB150.9-2009 | ||||

| Safety precautions | Power supply undervoltage, overvoltage, phase loss, and phase sequence error protection; Triple over temperature protection; Short circuit protection for heaters, Refrigerator overpressure/ overload/ oil shortage protection; Humidifier fault protection; Overload/ overheating protection for blower motor; Control board overcurrent protection, leakage protection; Cooling water shortage protection, etc. | ||||

| Optional | 1. Optional special test holes and special shelves; 2. Can remove the wet and hot function (model JT * CES); 3. Optional Dry air blowing system; 4. Optional liquid nitrogen function. |

||||

Copyright © 2024 SICHUAN JUPITER TECHNOLOGY CO.,LTD. All Rights Reserved Privacy Policy

message